Ecommerce Automation for Enterprise Solutions for Enterprise Retail & B2B

Simplify complex fulfillment, reduce manual effort, and customize workflows to fit your enterprise needs. A robust platform designed for high-volume, multi-team operations.

Built for Large-Scale Operations Automation & Customization for Scale

Automate & Scale Operations Enterprise-Grade Order Fulfillment

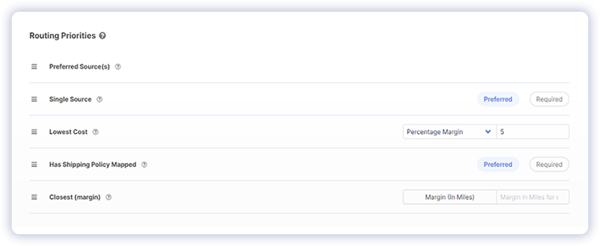

Process millions of orders with intelligent routing, bulk automation, and custom rules tailored to your complex supply chain.

Seamless EDI & ERP Integration Connect to Your Existing Systems

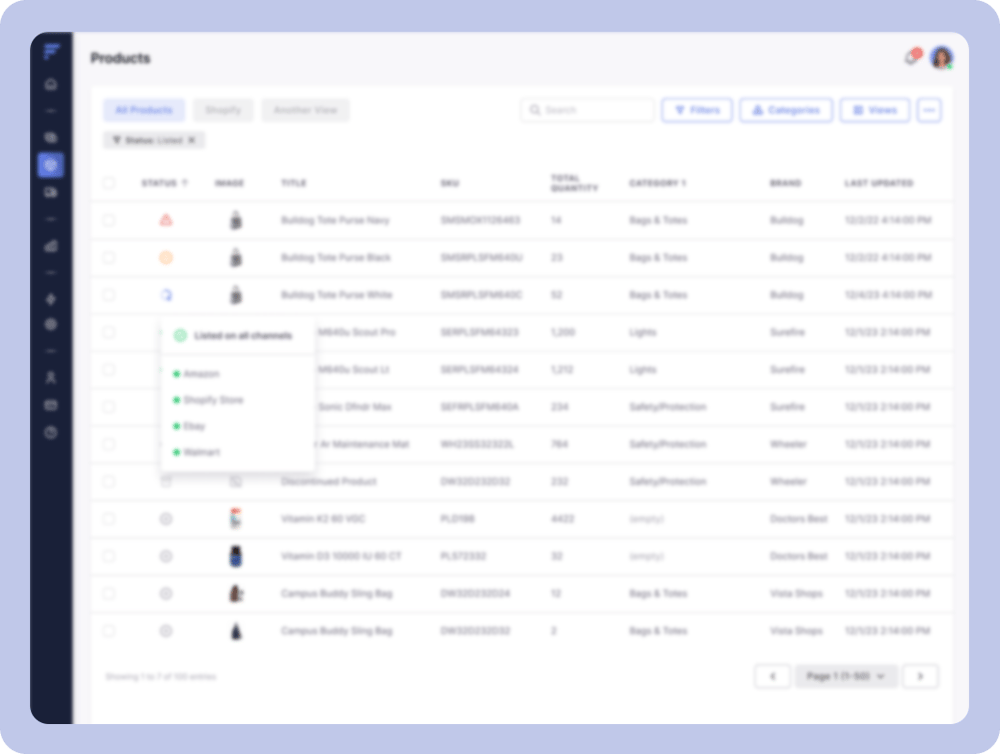

Sync seamlessly with inventory sources, sales channels, 3PL, WMS, IMS, and popular ERPs like Sage Intacct, NetSuite, and more. Automate EDI feeds to reduce errors and speed up fulfillment.

Smarter Supplier Management Centralized Control Over Vendors

Manage B2B, DTC, and retail partners in one system. Track performance, automate compliance, and customize workflows.

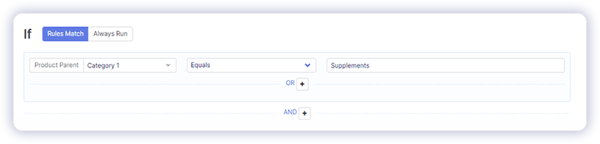

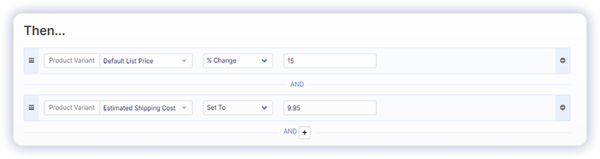

Reduce Manual Work by Over 80% Automate Complex Workflows

Eliminate spreadsheets with rule-based automation. Assign tasks, set permissions, and create company-wide efficiencies.

Calculator Your ROI

ROI Calculator

Results

Why Enterprise Brands Choose Flxpoint Reduce Complexity, Increase Efficiency

Minimize manual work with intelligent workflows that handle routing, inventory, and compliance automatically.

Seamlessly connect with ERPs, WMS, and retail partners using pre-built or custom API/EDI solutions.

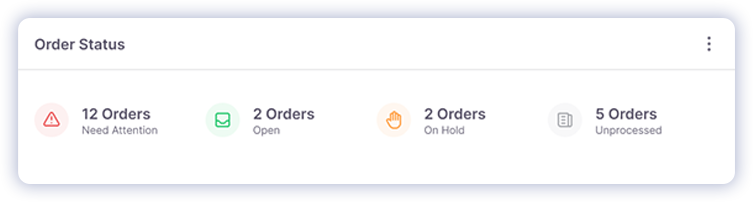

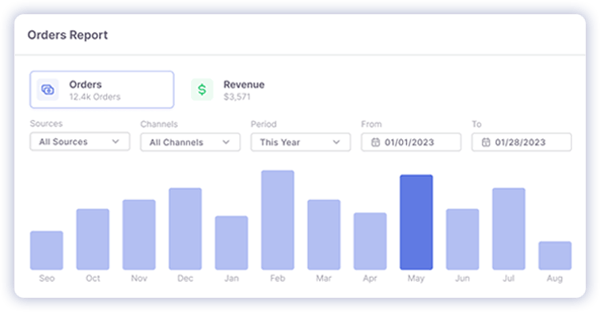

Gain deep insights into sales, fulfillment, and supplier performance with customizable dashboards.

Leverage flexible automation and tailored workflows that grow with your business.

Enterprise-Ready Connectivity Seamless Integration with Your Tech Stack

Connect with ERPs, WMS, 3PLs, marketplaces, and shipping carriers. Build fully automated workflows tailored to your needs with over 180 pre-built API and EDI integrations.