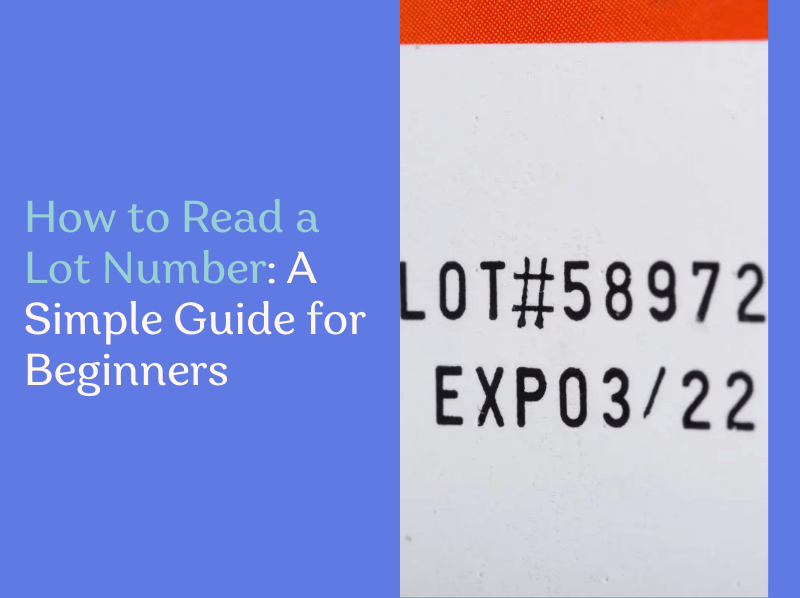

How to Read a Lot Number: A Simple Guide for Beginners

If you run an ecommerce business, you've likely encountered lot numbers on the products you sell or receive from suppliers. These seemingly random strings of characters might look unimportant, but they're actually powerful tools for inventory management, quality control, and customer service.

This guide will walk you through everything you need to know about lot numbers, from basic identification to advanced tracking strategies.

What Is a Lot Number in Ecommerce?

A lot number is a unique identifier assigned to a specific batch of products manufactured together under identical conditions. Unlike SKUs or UPCs that identify product types, lot numbers identify specific manufacturing batches. This distinction is crucial for ecommerce operations where you might sell the same product manufactured on different dates or in different facilities.

Lot numbers typically contain:

- Manufacturer identification code

- Production date or timeframe

- Batch or run number

- Plant or production line identifier

- Country code (for international commerce)

How to Read a Lot Number for Ecommerce Inventory

Decoding lot numbers can seem complex because there's no universal standard. Each manufacturer creates their own format, but most include similar elements that you'll need to understand for effective inventory management.

Let's break down a sample lot number: XYZ23041508A

- XYZ: Manufacturer code

- 230415: Production date (April 15, 2023)

- 08: Production line or shift

- A: Batch sequence identifier

What Is a Manufacturer Code?

The manufacturer code, often the first part of a lot number, identifies which company produced the item. This code might be the company's initials (like "JNJ" for Johnson & Johnson), a code assigned by a regulatory body like the International Organization for Standardization (ISO), or an internal identifier used by the manufacturer.

Knowing the manufacturer code helps you quickly identify the source of products, which is especially useful when you work with multiple suppliers for similar items.

What Is the Production Date?

The production date tells you exactly when the product was manufactured. This appears in several common formats. The "MMYY" format (like 0822) would mean August 2022. The "YYMMDD" format (like 220815) would mean August 15, 2022. Some companies use the Julian date format, where 22227 would mean the 227th day of 2022 (August 15).

The production date is crucial for managing inventory based on freshness, determining shelf life, identifying potentially problematic batches, and implementing proper first-in, first-out (FIFO) protocols.

Many retailers overlook the production date until they face quality issues or excess inventory problems. By proactively tracking this information, you can prevent these headaches before they start.

What Is a Batch Number?

The batch number identifies a specific production run. All products with the same batch number used identical raw materials, were processed on the same equipment, and were manufactured during the same time period.

Batch numbers are your best friend when quality issues arise. Instead of pulling all your inventory of a certain product, you can target just the affected batch, saving time and money.

For example, if customers report a defect in items from batch 5678, you can quickly identify all remaining inventory from that batch, remove those items from sales channels, alert customers who purchased from the affected batch, and communicate with your supplier about the specific production run. This targeted approach transforms a potential crisis into a manageable situation.

What Is Lot Tracking?

Lot tracking is the systematic process of monitoring products by their lot numbers throughout their journey in your supply chain. It helps you maintain precise inventory records, trace products back to their origin, handle quality issues with surgical precision, meet industry-specific compliance requirements, and deliver better customer service.

Modern inventory management systems automate lot tracking, making it easy to implement without adding significant manual work to your operations.

Benefits of Tracking Lot Numbers for Ecommerce Businesses

Implementing lot tracking delivers specific advantages for ecommerce operations:

1. Precision Recalls and Returns Management

When a product needs to be recalled, lot numbers let you target only the affected items. This surgical approach minimizes financial losses, reduces customer disruption, protects your brand reputation, and streamlines communication with suppliers and customers.

The same precision applies to returns. When a customer returns an item, checking the lot number can help you identify if it's part of a broader quality issue or an isolated incident.

2. Superior Inventory Control

Lot tracking transforms your inventory management by enabling true first-in, first-out (FIFO) rotation based on production dates. This reduces waste from expired or obsolete products, optimizes reorder timing based on sell-through rates of specific batches, and prevents stockouts of fast-moving items.

Retailers who master lot-based inventory management typically report 15-20% reductions in inventory waste and carrying costs.

3. Enhanced Quality Assurance

When customers report issues, lot numbers help you quickly identify if the problem affects a single item or an entire batch. You can trace issues back to specific production runs, collect data on quality trends by manufacturer, facility, or time period, and provide detailed information to suppliers for faster resolution.

This data-driven approach to quality management strengthens your relationships with both customers and suppliers.

4. Fraud and Counterfeit Prevention

Lot numbers serve as a powerful tool against counterfeit products entering your inventory. By validating lot numbers against manufacturer records, you can identify suspicious items before they reach your customers. This helps pinpoint where counterfeits are entering your supply chain, protects your brand reputation and customer trust, and helps you avoid potential legal issues from selling unauthorized products.

Many retailers don't realize the protective power of lot tracking until they've experienced a counterfeit situation.

5. Regulatory Compliance

Many industries have strict traceability requirements that lot numbers help you meet. Food and beverage retailers must comply with Food Safety Modernization Act (FSMA) standards, and many now rely on FSMA 204 compliance software to streamline tracking and documentation. In this sector, a well-structured restaurant online ordering system can also support compliance by keeping accurate records of orders, ingredients, and inventory. Cosmetics sellers need to follow FDA regulations. Electronics distributors must meet various safety standards. Medical and pharmaceutical retailers have especially stringent requirements.

Proper lot tracking keeps you compliant without creating administrative burdens.

6. Customer Confidence

When customers see you taking product tracking seriously, it builds trust in your brand. You can quickly address product concerns with specific information, provide transparency about product origins, demonstrate your commitment to quality, and turn potential negative experiences into positive ones.

This trust translates directly into customer loyalty and repeat business.

Who Uses Lot Number Tracking in Ecommerce?

Lot tracking is relevant across various ecommerce business models:

Dropshipping Operations

Dropshippers use lot information to:

- Track which supplier fulfilled specific customer orders

- Manage quality issues with specific supplier batches

- Route customer inquiries to the appropriate supplier

- Document compliance with marketplace requirements

Multi-Channel Retailers

Businesses selling across multiple platforms leverage lot tracking to:

- Maintain consistent inventory quality across channels

- Apply channel-specific rules for lot age or quality

- Prevent cross-channel confusion during recalls

- Allocate fresh inventory to premium channels

FBA and 3PL-Based Ecommerce

Businesses using Amazon FBA or third-party logistics benefit from lot tracking to:

- Verify proper lot rotation in external warehouses

- Reconcile inventory discrepancies with specific batches

- Manage commingled inventory risks

- Coordinate multichannel inventory across fulfillment locations

Direct-to-Consumer Brands

D2C brands use lot tracking to:

- Monitor product consistency between production runs

- Build customer trust through transparency

- Control the customer experience across the product lifecycle

- Gather batch-specific feedback for product improvement

Marketplace Sellers

Marketplace sellers leverage lot information to:

- Verify authentic products from authorized distributors

- Protect against marketplace suspensions during recalls

- Document product provenance for platform requirements

- Manage return rates by tracking problematic batches

How to Read a Lot Number After It Expires for Ecommerce Returns

Even after products expire, lot numbers remain valuable for ecommerce operations:

For Returns Processing

When a customer returns an expired product, the lot number helps you verify the product's authentic origin and determine how long past expiration the item is. You can check if it was part of a known quality issue and make appropriate decisions about refunds or replacements. This information protects both your business and your customers from potentially problematic products.

For Inventory Analysis

Examining expired lot patterns helps you optimize future purchasing by identifying slow-moving SKUs that consistently expire before selling. You can recognize seasonal patterns in product turnover, adjust order quantities based on historical sell-through rates, and make data-driven decisions about your overall product mix. These insights turn past expirations into future inventory improvements.

For Supplier Negotiations

Information from expired lot numbers strengthens your position when discussing product shelf life improvements with suppliers. You can negotiate more favorable dating terms, address chronic quality issues, and build vendor scorecards based on actual performance data. When you have concrete information about expiration patterns, suppliers are more likely to work with you on improvements.

Implementing Lot Tracking in Your Ecommerce Business

Ready to elevate your ecommerce operations with lot tracking? Follow these steps:

1. Evaluate Your Product Mix

Different products require different levels of lot tracking:

- High-Risk Products: Items with safety concerns, high value, or regulatory requirements need detailed lot tracking

- Perishable Products: Anything with an expiration date benefits from lot-level rotation

- High-Volume Products: Focus on your bestsellers where recalls would cause significant disruption

- Variable Quality Products: Items where manufacturing consistency varies between batches

Start with your most critical categories and expand as you build expertise.

2. Select the Right Technology Stack

Modern ecommerce demands specialized tools for lot tracking:

- Inventory Management Systems: Look for platforms with built-in lot tracking capabilities

- Warehouse Management Software: Ensure it supports lot-based picking and putaway

- Barcode Systems: Implement scanners that capture lot information during receiving

- Order Management Integration: Connect lot data to customer orders for future reference

- Reporting Tools: Develop custom reports for lot aging and expiration alerts

For multi-channel sellers, ensure your chosen solution synchronizes lot information across all platforms.

3. Establish Supplier Requirements

Create clear expectations with your suppliers:

- Define your required lot number format for consistency

- Request advance shipment notifications with lot details

- Establish communication protocols for recalls or quality issues

- Require digital documentation of lot information for easy import

- Set standards for lot number placement and readability on packaging

Many suppliers will accommodate reasonable lot tracking requests if they understand your needs.

4. Develop Standard Operating Procedures

Create clear workflows for your team:

- Receiving Process: Scan and record all lot numbers during intake

- Putaway Rules: Store products with the same lot number together

- Picking Guidelines: Implement FIFO procedures based on lot dates

- Quality Inspection Protocols: Reference lot numbers in all quality checks

- Customer Service Scripts: Train staff to request lot information for quality complaints

Document these procedures in your operations manual and review them regularly with your team.

5. Start with Manual Processes Before Scaling

Begin with manageable steps:

- Record lot numbers in a spreadsheet during receiving

- Apply lot number labels to storage locations

- Include lot numbers on packing slips

- Track customer complaints by lot number

- Create basic aging reports for inventory review

As these manual processes become routine, transition to automated systems for greater efficiency.

Overcoming Common Lot Number Challenges in Ecommerce

Ecommerce businesses face unique challenges when implementing lot tracking systems. Understanding these obstacles and having strategies to address them can make the difference between a functional system and one that creates more problems than it solves.

Supplier Consistency Issues

Different suppliers often use different lot number formats, making standardization difficult. To address this common challenge, create a standardized internal format that all lot numbers are converted to when received. Maintain a translation table that documents each supplier's specific format and how it maps to your internal standard.

Training your receiving staff to recognize and properly record various lot number formats is essential. Include lot number standardization requirements in your supplier agreements whenever possible. Many inventory management systems also allow you to implement validation rules that can catch formatting errors before they enter your system.

Marketplace Integration Limitations

Many ecommerce marketplaces lack robust support for lot tracking, creating visibility gaps in your supply chain. Even when marketplaces don't support lot tracking natively, you can store lot information in your internal systems and maintain the connections behind the scenes.

Order notes or metadata fields can be used to maintain associations between marketplace orders and specific lots. Regularly downloading and storing marketplace order data alongside your internal lot records creates a complete picture of product movement. Creating simple lookup tools for your customer service team ensures they can access lot information when needed for customer inquiries or returns processing.

Warehouse Space Constraints

Physical space limitations can make it challenging to segregate inventory by lot, especially for businesses with wide product assortments. When complete physical separation isn't possible, implement clear lot labeling within mixed storage locations. Color-coded tags for different date ranges or production batches can make visual identification faster and more accurate.

Organizing your picking routes to naturally follow first-in, first-out principles helps ensure older inventory moves first. For products with shorter shelf lives, consider creating "aging zones" where inventory approaching expiration can be monitored more closely and prioritized for fulfillment.

Scale and Volume Challenges

As your ecommerce business grows, manual lot tracking becomes increasingly difficult to maintain. A tiered approach often works best, with the highest level of tracking applied to high-risk and high-value items, while using more streamlined approaches for lower-risk products.

For very high-volume products with minimal risk profiles, implementing statistical sampling approaches to lot tracking can provide adequate visibility without overwhelming your operations. Automation plays a key role in scaling lot tracking effectively, handling routine tasks while allowing your team to focus on exception management and quality control.

Conclusion

For ecommerce businesses, mastering lot numbers transforms basic inventory management into a strategic advantage. Whether you're managing quality, navigating recalls, optimizing freshness, or building customer trust, lot tracking provides the granular control modern ecommerce demands.

Start by understanding the basics of how to read lot numbers, then gradually implement tracking systems that match your specific business model and product mix. With each step toward better lot management, you'll gain more control over your inventory, reduce risks, and create more consistent customer experiences.

Remember that lot tracking isn't just about compliance or quality control. It's a fundamental capability that supports growth, builds trust, and helps your ecommerce business stand out in an increasingly competitive marketplace.

Get a demo of Flxpoint today and discover how our distributed inventory platform can solve your specific pain points.

Flxpoint – Powerful Dropship and Ecommerce Automation Platform